Warp knitted fabrics are transforming multiple industries with their unique properties, adaptability and efficient production processes. From sportswear to industrial uses, this textile innovation is reshaping our perception of fabric structure and performance.

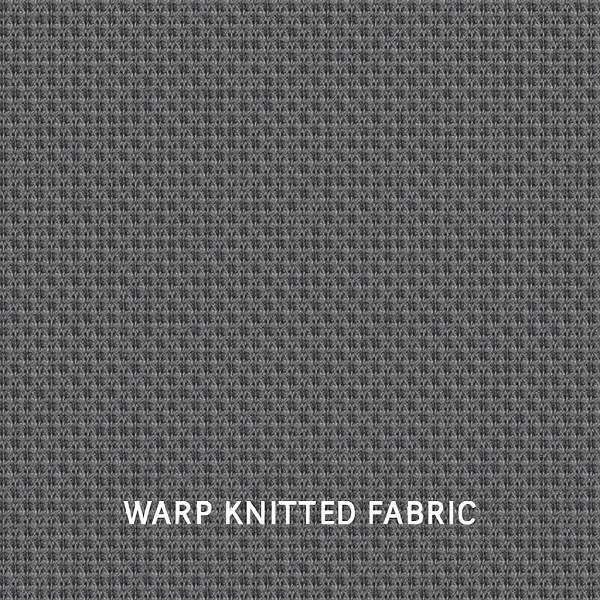

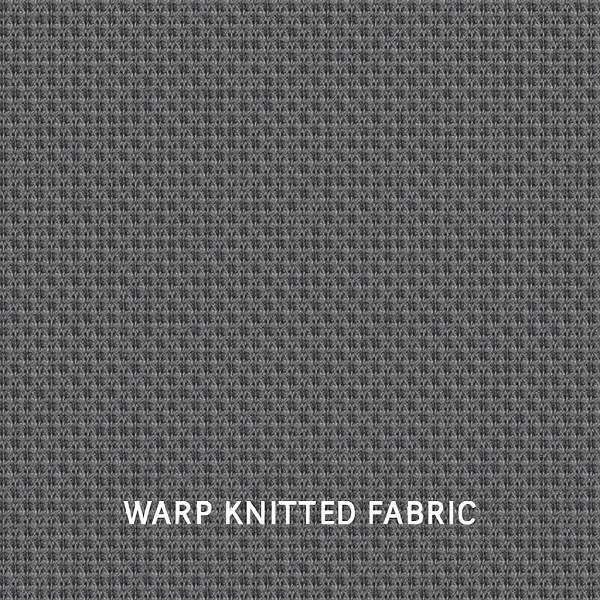

1. What is warp knitted fabric?

- Definition and structure: Warp knitted fabric is a textile produced by the warp knitting process, where the yarns run vertically along the fabric. This is different from weft knitting, where the yarns run horizontally along the fabric.

- Types of warp knitted fabrics: Common types include tricot, raschel and milanese, each designed for a specific end use.

Features:

- High dimensional stability

- Low shrinkage

- Excellent breathability

- Fast production speed

Material used: It can be made from synthetic fibers such as polyester and nylon, or natural fibers such as cotton and bamboo.

2. Key benefits of warp knitted fabrics

- Strong and durable: Warp knitted fabrics are extremely strong and are ideal for demanding applications such as sportswear and geotextiles.

- Shape retention: Due to its vertical loop structure, it retains its shape better than many other fabrics.

- Quick drying: The open structure allows for quick moisture wicking, making it ideal for sportswear and outdoor clothing.

- Wrinkle resistance: The fabric is wrinkle-resistant, making it suitable for travel clothing and uniforms.

- Cost-effectiveness: The high speed of warp knitting machines reduces production costs while maintaining product quality.

3. Application of warp knitted fabrics in various industries

Apparel industry:

- Sportswear: Its breathability, elasticity and durability make it a staple fabric for sportswear.

- Underwear: Fine warp knitted fabrics such as tricot are soft and stretchy.

- Swimwear: Chlorine-resistant fabrics are widely used.

- Home textiles: Warp knitted fabrics are often used in curtains, interior decoration and bedding because they are beautiful and easy to maintain.

- Automotive: Warp knitted fabrics are used in car seat covers and linings for comfort and durability.

- Health care: It is used in bandages, supports and hygiene products because of its soft and skin-friendly properties.

- Industrial and technical uses: Warp knitted fabrics are used in applications such as reinforcement, filtration and geotextiles due to their strength and structural advantages.

4. Sustainability and warp knitted fabrics

- Recyclable fibers: Today, many warp knitted fabrics are made from recycled synthetic fibers.

- Low waste generation: Knitting processes produce very little fabric waste compared to weaving production.

- Energy efficiency: Warp knitting machines use less energy than traditional looms, contributing to more environmentally friendly manufacturing.

5. Future innovations in warp knitted fabrics

- Smart textiles: The integration of conductive yarns allows warp knitted fabrics to be used in wearable electronics and health monitoring devices.

- 3D knitting: Advanced machines can now produce three-dimensional warp knitted fabric structures, expanding design and performance possibilities.

- Sustainability: Research focuses on bio-based yarns and closed-loop manufacturing, making warp knitted fabrics more environmentally friendly.

- Customization and digitalization: With technological advances, warp knitted fabrics can now be designed with specific tensile strength, porosity and elasticity for customized industrial applications.

Warp knitted fabrics are the cornerstone of modern textile manufacturing, offering unrivalled versatility, strength and innovation. Their applications span a wide range of sectors including fashion, automotive, healthcare and technical textiles.